Our Services

- Project management and advisory function for steel structures

- Intelligent 3D Steel Modeling

- Intelligent 3D Modeling in general

- BIM Modeling

- DSTV-NC and DSTV-DXF integration

- File output for automated processing and positioning (scribing)

- Advanced Bill of Materials (ABM)

- 2d fabrication and workshop drawings

- 2d Marking plans

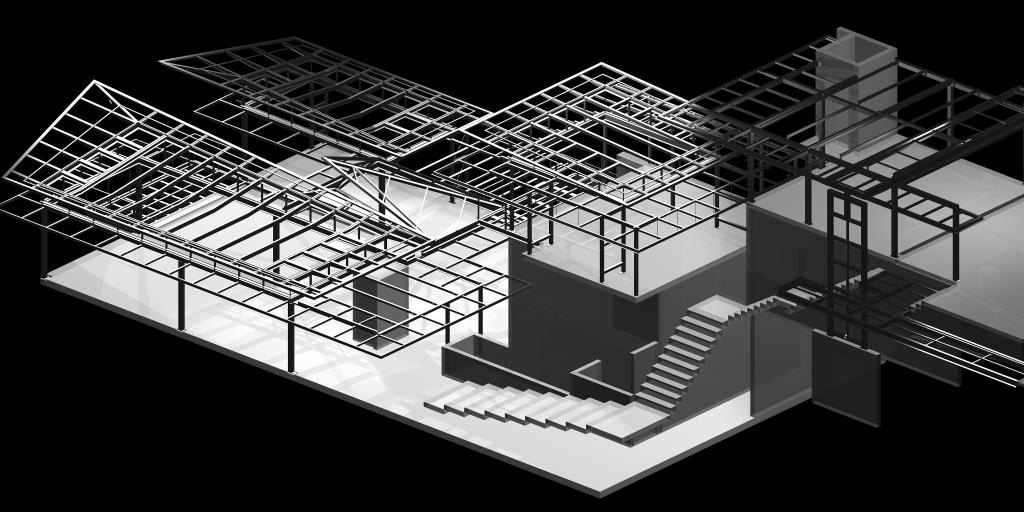

3D Steel Modelling

DemCox has been utilising dedicated 3D modelling software since its inception. With this software, we create a highly accurate virtual Model of the structure which is data rich with all relevant Information necessary for procurement, fabrication & erection of every steel component in your structure.

We have an in-house, dedicated specialist who uses their technical expertise and knowledge of the program to maximize efficiencies and productivity. Because of this, DemCox can customise our extracted 2d drawing output (Marking Plans, Assembly and Item/Plate drawings), fabrication and procurement reports as well as numerous other custom reports, to meet and often exceed our client’s requirements and expectations.

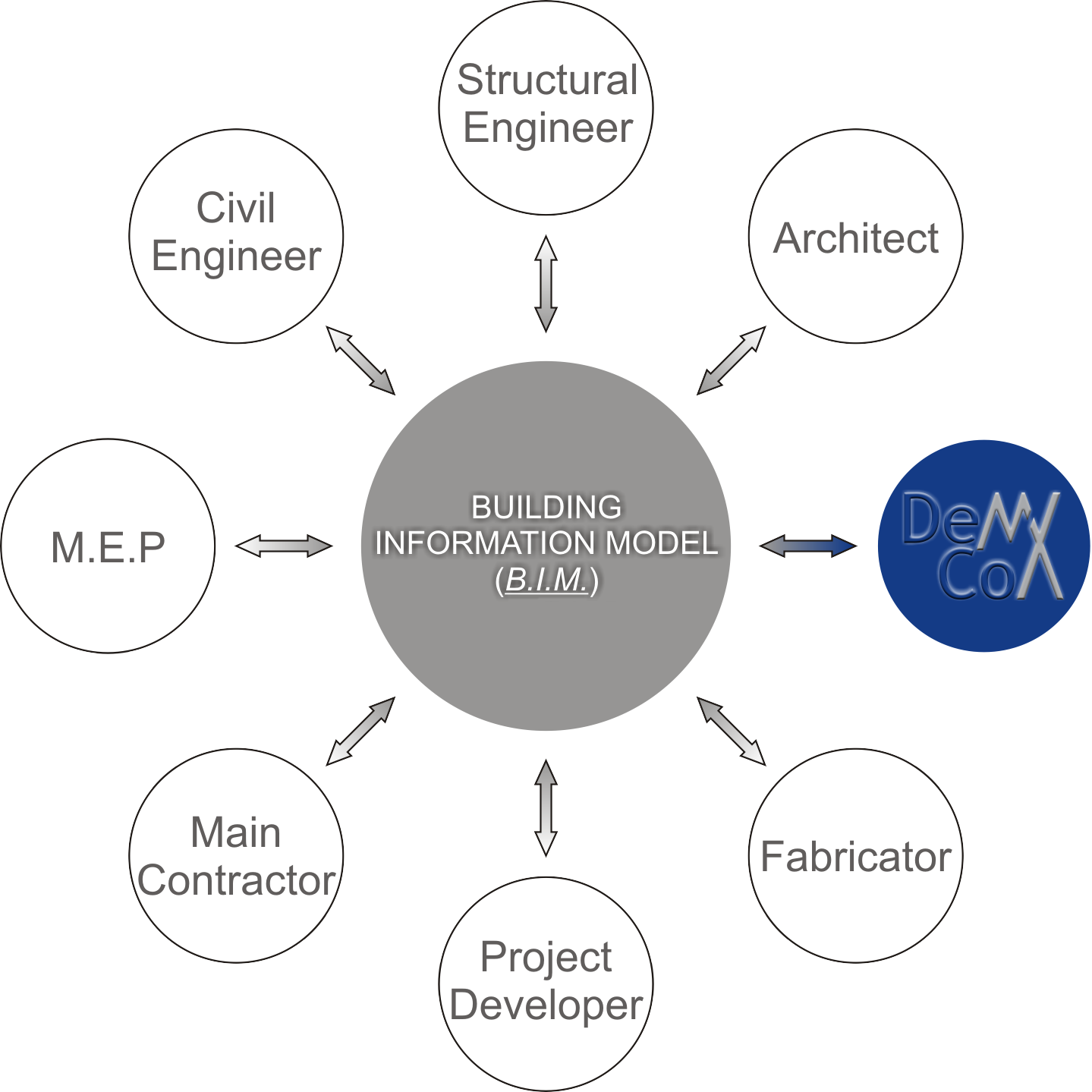

B.I.M Modelling

Q: What is BIM? A: The process of modelling and communicating the structure of a building in detail to benefit the entire building lifecycle. BIM facilitates the exchange and visualization of building information in digital 3D format between all building disciplines to ensure integrated project delivery (IPD). The acronym BIM stands for building information model or building information management.

DemCox have been BIM modelling since our inception and are constantly striving to keep up with or ahead of the technology.

Structural designers start from raw data and build their prototypes or ‘models’ based on their analysis output. As more information is gathered, changes are applied to the model. The advantage of the BIM approach and early engagement of a steel detailer is that modifications to the 3D structural model take place in a finely controlled environment allowing ease and effective management of the entire building model. With true BIM software, information is shared from design concept to detailing, fabrication and erection. Start to Finish.

We have built many Building Information Models (BIM) from the structural steel perspective. Our ultimate goal however is that after we build the model for the owner, building contractor, engineer etc., we can proceed to prepare the shop detail drawings before the project goes to the fabricator for tender. This process allows the builder to get the very best price from both the fabricators and constructors as they are all quoting from the finished drawings and have access to accurate tonnages and finishes.

More and more clients are seeing the benefits of this approach and we hope it will eventually become the norm for progressive thinking owners and contractors. DemCox can support and supplement the engineering team to help solve the design and documentation problems before the project goes to the fabricator.

The fundamental nature of our 3D model – is to ensure that project data is current, available and reliable. Innovators who embrace this concept early on have seen significant increases in productivity, providing them with a considerable edge over the ‘exchange of paper’ industry.

Our typical scope of supply is as follows:

Deliverables:

- Anchor plans and details - These show all of the different types of HD bolt groups and single anchors including their exact location and RL on site.

- Plate and item drawings - These drawings are produced “part per page” and include all flat and plate steel plus all hot rolled steel members such as UB’s, UC’s, PFC’s, Ea’s, RHS, CHS etc.

- Assembly drawings - These drawings are also produced “part per page” and show the main member plus all fitments (plates and items) that are welded to it. It is fully dimensioned for the placement of all fitments and also shows direction indicators and the finish required to the assembly. The material list will also show any bolts required to erect it into position on site

- Purlin, girt and bridging details - These drawings and lists show all cold rolled elements required including all punched hole locations, bridging locations, cuts required and bridging lengths and quantities.

- Grating, floorplate and handrail drawings - All suppliers for these items have different needs and requirements. Drawings for these items are produced to suit the specific supplier

- Marking plans - These drawings consist of isometric overview drawings, plans, elevations, sections and details that the erection team need to place the assemblies in the correct position on site. These drawings show critical information such as RL’s, dimensions to grids, construction north point etc.

- Lists - Including steel order lists, purlin order lists, purlin assembly lists, item and plate lists, assembly containment lists, bolt order lists, assembly bolt lists and shipping lists. Lists can be configured to show almost any information the client requires for specific projects (such as surface area per assembly for painting costs).

- DSTV-NC & DSTV-DXF files - DXF files are supplied for automated cutting of plates. NC files are supplied for beam-lining of steel members. If required, scribe lines (aka powder lines) can be added to the NC files showing locations of plates and items to be welded to the main members.

- 3D model file - The 3D model file is supplied in a format required by the client (such as IFC, DWFx, DWG, SDNF etc).

Non Tangables:

Project management

DemCox has a policy of proactive interaction with the consultants, builder and fabricator. Our team of experienced engineers and checkers are trained to identify potential erection, safety and design issues. Internal round table reviews of all models are conducted whereby any discrepancies are raised with the client. An open invitation to clients to take part in the model review is also encouraged within this process.

All projects are assigned a project manager and dedicated full-time drafters.

The project manager is responsible for ensuring that the client's requirements are met and provides progress reporting and resource scheduling to management. The project manager is a single point of contact for the client, ensuring that a professional and consistent relationship is developed.

Quality assurance

All checks are performed by senior engineers. Their role is to ensure that the design intent is followed and that the resulting steel details can be fabricated and erected by conventional fabrication techniques.

This dedication to quality, combined with the inherent precision of 3D solid modelling software, brings a high degree of accuracy, minimising errors, fabrication time and erection time.

For peace of mind, DemCox is fully insured and is also working towards an ISO9001 standard.